Que recherchez-vous ?

Un contenu sur ce site

Une personne sur l'annuaire

Une formation sur le catalogue

Un contenu sur ce site

Une personne sur l'annuaire

Une formation sur le catalogue

Theme Coordinators

Ludovic Thilly (ludovic.thilly@univ-poitiers.fr / +33 5 49 49 68 31)

Pierre-Olivier Renault (pierre.olivier.renault@univ-poitiers.fr / +33 5 49 49 67 45)

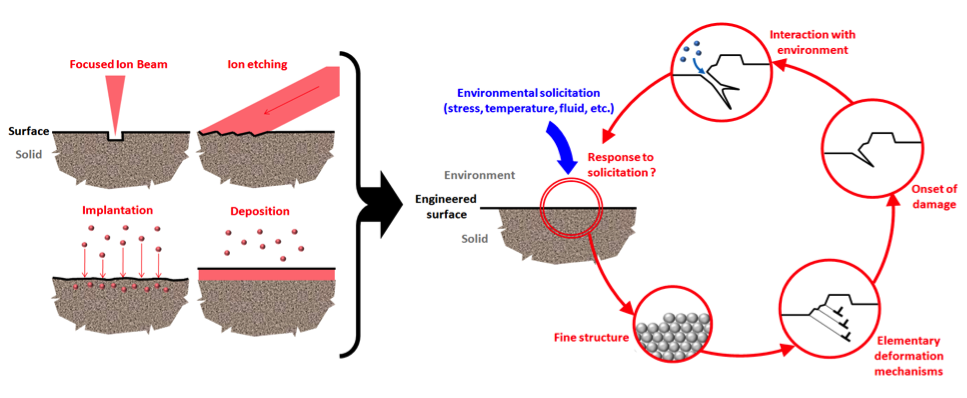

The development of multifunctional materials with surface/interface specific properties is a research topic at the « heart » of the Pprime Institute. The physical and mechanical properties of the surface can be controlled by addition of new phases, microstructure changes, or texturing of the surface at the nano/micrometer scale. Small changes in the surface can indeed induce dramatic changes in the macroscopic behavior. Studies conducted in the framework of LABEX INTERACTIFS rely on several cutting edge techniques for surface engineering: texturing and etching by ion bombardment, ion implantation, ion deposition. These techniques are based on the interaction between matter and ions that are either sprayed or deposited on the surface or implanted underneath. Particular attention is paid to the effects induced by these ion-matter interactions, in order to avoid any change in physical properties or production of unwanted defects in the processing of the surface. For this, the complete characterization of the microstructure of the treated surface must be performed by a variety of microscopy techniques (FEG-SEM, EBSD, TEM, AFM, STM), prior to any physical property measurements.

The difficulty comes from the studied small scales that require the development of specific tools for surface processing and associated small scale metrology. Mastering these tools is a major issue with wide impact in terms of fundamental and applied research. If we are able to control the structure of the first atomic layers, it is possible to control the mechanisms that develop in this region and hence the induced surface properties.

The Theme is divided into 3 research topics:

Contact points : Anne Joulain / Joël Bonneville

The first action is based on recognized expertise in the study of the elastic and plastic properties of low dimensional systems (thin films, micro- and nano-pillars) in extreme conditions or at small scales. To do this, we use cutting-edge and complementary techniques (x-ray diffraction, nano-indentation, in situ monitoring of stressed surfaces with atomic resolution by AFM/STM under UHV environment). The scheduled arrival of the Focused Ion Beam microscope (FIB) will allow for the preparation of targeted surfaces and nanostructures for specific studies, such as the understanding of the early stages of plasticity. In parallel, we have expertise in theoretical and numerical simulation to effectively complement the experiments.

Contact points : Yves Nadot / Gilbert Henaff

The second action aims at studying how the surface of a metallic material influences the plasticity/damage transition via the presence of surface defects (with variable size and geometry) and/or a specific external environment (e.g. in the presence of hydrogen). The arrival of the FIB will notably enable the creation of controlled surface defects in order to study their effects. Meanwhile, other activities are already underway on modeling the origin of persistent slip bands before the transition to the damage (simulations using the finite elements method with crystal plasticity approach; study of the interaction of these bands at the surface or link grain boundaries with the initiation of fatigue intra- or inter-granular cracks) or the fabrication of specific cast aluminum with a controlled microstructure and defects population.

Contact points : Valéry Valle / Pascal Doumalin

The third action is associated with the current development of electron-based imaging techniques at small scales, allowing for considering the development of field metrologies based on those already used at optical scale. However, it is not a simple transposition, because it is first necessary to test the stability of these new imaging techniques. In addition, there must be an effective marking of the sample surface. The quality of results depends on the quantification of both aspects, stability and marking. Currently, we are developing the field of metrology at fine scales, but at the limit of the optical scale, on heterogeneous materials composed of grains in a matrix. These optical tests are performed with a spatial resolution of 2,2μm and a dynamic resolution of the order of 50 nm. This work will include the development of specific algorithms to overcome the presence of field discontinuities or measure these discontinuities. The objective is to quantify, in a fine way, the displacement field at the grain-matrix interfaces. Using a FIB seems to be the ideal tool for this development because it allows for the creation of controlled markings and offers improved imaging quality.

These three topics are associated to research at different length scales, from nanometer to macroscopic behavior. Their combination amis at the understanding / prediction / control of the physical and mechanical phenomena involved at the surfaces / interfaces. This multi-scale and multi-physics approach is illustrated by the following schematic.

Surface nano-engineering: scientific issues in surface physics and mechanics, from elasticity to damage.

Surface nano-engineering: scientific issues in surface physics and mechanics, from elasticity to damage.